I – Partie Capteur d’une chaine instrumentale

1 – R&D capteur de champ électrique

Un financement CNES a été obtenu pour cette action de R&D qui s’inscrit dans le cadre de la préparation des instruments scientifiques de demain pour la mesure du champ électrique (recherche technologique en amont, maîtrise des micro-technologies). L’objectif était de proposer une solution microsystème pour la mesure du champ électrique dans la bade de fréquences allant du DC à 1 kHz. La solution MEMS a permis une mesure directe du champ électrique et un encombrement très réduit.

Le LPC2E développe depuis plusieurs d’années des antennes électriques courtes pour la mesure des champs alternatifs de quelques kHz à plusieurs dizaines de MHz. La dernière réalisation du LPC2E a été embarquée en 2004 sur la sonde cométaire ROSETTA. Un capteur de type antenne sera embarqué dans la mission TARANIS en 2018.

Plusieurs actions de R&D ont été menées ces dernières années pour améliorer les performances des antennes électriques, comme par exemple la solution ASIC du préamplificateur haute impédance d’entrée (voir R&D préamplificateur antenne électrique). Aucune amélioration majeure ne semble pouvoir être possible sans une rupture technique forte. Avec cette R&T, nous avons étudié la possibilité de faire une mesure directe du champ, alors que les capteurs actuels (antenne) déduisent le champ d’une différence de potentiel entre deux monopoles.

Des études préliminaires ont été effectuées au LPC2E dans le cadre de stages de master 2, d’une part, pour valider l’aspect théorique du capteur et, d’autre part, pour imaginer et simuler un concept architectural permettant de répondre à notre cahier des charges. Les résultats obtenus nous ont encouragé et conforté à continuer dans cette voie. Les recherches se sont poursuivies à travers un financement R&T CNES et par une bourse de thèse en cotutelle avec IRIS industrie. La thèse a permis d’établir des collaborations internationale avec l’Université de Louvain la Neuve en Belgique et nationale avec le laboratoire IEMN de Lille et le CMP à Grenoble. Le financement de la bourse était assuré par le conseil général du Loiret CG 45. La thèse de Mr Boujhrarhe a été soutenue en 2013. Ce travail a donné lieu au dépôt d’un Brevet et à des publications.

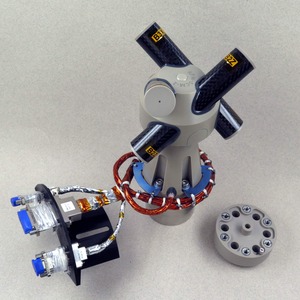

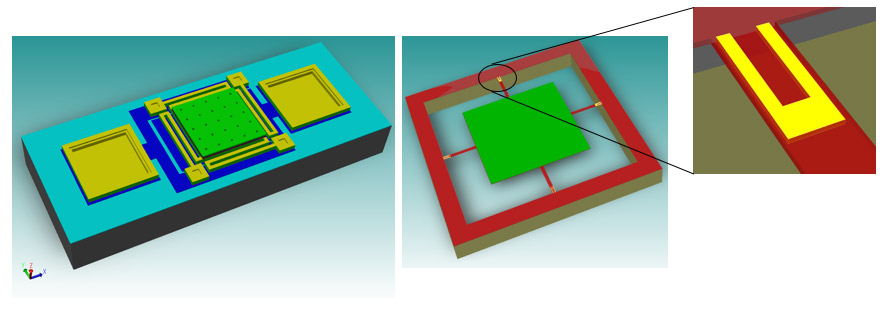

Architecture MEMS du capteur de champ électrique (G) architecture capacitive, (D) architecture à base de piézorésistance

Un prototype du capteur a été fabriqué à l’IEMN. Cette fonderie a permis de valider le fonctionnement théorique du capteur comme le montre les figures ci-dessous.

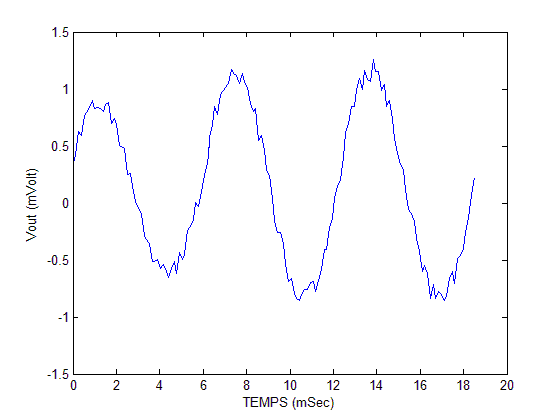

(a) Réponse transitoire du capteur pour une excitation de 1 mV/m à une fréquence de 170 Hz

(b) Réponse du capteur à une variation de la fréquence du signal d’excitation fixé à 1 mV/m.

En AC, le capteur “suit” l’évolution du signal d’excitation mais avec un déphasage (temps de réponse du capteur), figure (a). Le prototype permet de mesurer un faible champ pouvant atteindre 2.8×10-5 V/m. La réponse du capteur “reste” plate du DC jusqu’au premier pôle autour de 11 kHz, figure (b).

2 – R&D capteur de champ magnétique

Cette action a permis l’obtention d’un financement CNES et s’inscrit dans le cadre de la préparation des instruments scientifiques de demain pour la mesure du champ magnétique large bande. L’objectif est de proposer une solution microsystème pour la mesure du champ magnétique allant de quelques Hz à 50 kHz. La solution microsystème permettra à terme de remplacer les capteurs de type search coil (400 g, 20 cm de diamètre), une grande miniaturisation et un encombrement très réduit.

Dans le cadre de ses recherches sur les environnements ionisés des planètes du système solaire, le LPC2E développe depuis un certain nombre d’années des capteurs électriques et magnétiques destinés à être embarqués sur des satellites ou bien des sondes interplanétaires. Bien que performants (sensibilité de quelques fT/Hz1/2 en VLF-MF) et répondant parfaitement à la demande concernant la fiabilité, ils restent relativement lourds et encombrants, ce qui implique des systèmes de déploiement relativement lourd eux aussi et souvent complexes. On peut citer à titre d’exemple l’intégration d’un capteur triaxial search coil sur le satellite DEMETER en 2004 ainsi que sur la future mission TARANIS prévue pour 2018. Plusieurs actions de R&T ont été menées ces dernières années pour réduire l’encombrement et améliorer les performances des capteurs search coil, comme par exemple la diminution de la taille des barreaux magnétiques et la miniaturisation de l’électronique de réception. Toutefois, aucune amélioration majeure ne semble maintenant être possible sans une rupture technique forte. En effet, le principe de fonctionnement de ce capteur est basé sur l’induction et nous arrivons aux limites (en matière de sensibilité) de ce que peut permettre cette technique. L’émergence de nouvelles technologies MEMS ainsi que de techniques reposant sur les couches minces et notamment la « spintronique », permettent d’envisager dans un avenir proche des capteurs beaucoup plus légers et moins encombrants. Dans le cadre d’une R&T dont nous avons obtenu un financement CNES, Nous avons mené pendant quelques années une étude approfondie sur les magnétorésistances géantes (GMR), dans le but de développer un capteur de quelques cm³ et pesant quelques grammes, tout en ayant des performances se rapprochant de ceux développés jusqu’ici. Bien que les résultats obtenus soient encourageants (taille, poids et encombrement) nous n’avons pas réussi à atteindre des performances (sensibilité, bruit) semblables à celles du search-coil.

Ce travail est actuellement sous la responsabilité d’un ingénieur CNRS du LPC2E qui a continué les développements en utilisant cette fois ci un capteur à effet tunnel de type SDT (Spin Dependent Tunneling). Ces nouveaux développements ont abouti au projet MAROT.

3 – R&D Amélioration de la réponse d’un capteur piézoélectrique céramique

C’est une action qui s’est déroulé en amont de la R&D capteur de champ électrique. En effet, lors de la prospection des nouvelles technologies et capteurs pouvant nous permettre le développement d’un capteur de champ électrique miniaturisé, nous nous sommes alors intéressés aux capteurs piézoélectriques. Bien que la solution piézoélectrique n’ait pas été retenue pour le développement de notre capteur, nous avons néanmoins développé une méthode de polarisation qui permet d’améliorer la réponse électrique des capteurs piézoélectriques lorsqu’ils sont soumis à une excitation mécanique.

En effet, la récupération de l’énergie mécanique de vibration issue de l’environnement pour la convertir en énergie électrique est la clé pour développer des systèmes de capteurs autonomes. Pour faire cette étude, nous avons créé un modèle paramétrique FEM de capteur piézoélectrique. Ce modèle, développé sous environnement Comsol, a permis de valider notre concept de polarisation. Le concept a été validé expérimentalement sur banc de test. La polarisation a ainsi permis d’améliorer la réponse des capteurs piézoélectriques, dans notre cas il s’agissait d’un capteur sous forme de lamelles céramiques, d’un facteur de 18% tout en réduisant le risque de destruction des lamelles. Ce travail a donné lieu à deux publications.

4 – R&D Capteurs refroidies (supraconducteurs) pour applications spatiales

A très basse température, les propriétés électriques et magnétiques de certains matériaux tels le plomb, le mercure ou certains oxydes changent radicalement. Ces matériaux deviennent supraconducteurs : ils n’opposent plus aucune résistance au passage du courant électrique et expulsent les champs magnétiques.

Les supraconducteurs sont déjà utilisés dans de nombreux domaines : électricité, médical et même dans le domaine spatial. Ils sont aussi au cœur des laboratoires, dans les accélérateurs de particules, dans le domaine de l’astrophysique avec les bolomètres, dans des capteurs magnétiques ultrasensibles tel que les SQUID, ou pour produire des champs magnétiques très intenses. Cependant, il faut les refroidir à de très basses températures.

Dans cette étude, nous avons discuté de la pertinence de l’utilisation des capteurs refroidis dans le domaine spatial. Nous avons donné une image instantanée des récents développements concernant les matériaux supraconducteurs, les capteurs refroidis destinés au domaine spatial, les technologies permettant la génération/production du froid, sans oublier de lister toutes les missions spatiales susceptibles d’embarquer du froid.

Cette R&D a abouti à un contrat avec la société ALCATEL Space pour laquelle nous avons fourni un rapport de prospection sur cette technologie pour les futures missions spatiales ainsi qu’à une publication.

II – Partie Amplificateur d’une chaine instrumentale

1 -R&D Préamplificateur ASIC basse température pour capteur search-coil

L’objectif de cette R&D est de développer un préamplificateur en technologie ASIC permettant un fonctionnement de l’instrument search-coil BF 10Hz-20KHz dans une large gamme de température.

Le LPC2E mène des activités de recherche sur l’environnement ionisé de la Terre, des planètes et la relation Soleil-Terre. Actuellement et jusqu’à 2018, l’équipe ESPACE, dont je fais partie, est engagée dans la réalisation d’instruments dans différents projets internationaux : Solar Orbiter et Parker Solar Probe dédié à l’étude du Soleil.

Solar Orbiter (SO) et Parker Solar Probe (PSP) sont respectivement des missions de l’ESA et de la NASA. Parmi les objectifs scientifiques de ces missions l’étude de l’accélération du vent solaire, le chauffage de la couronne solaire ainsi que l’accélération des rayons cosmiques d’origine solaire. La participation du LPC2E à ces missions se fait à travers les instruments RPW-SCM pour SO et SCM pour PSP. Il s’agit dans les deux cas de magnétomètres tri-axe du type search-coil.

Comme nous le venons de le voir, pour les missions préalablement citées, le développement de magnétomètres search-coil est essentiel pour le LPC2E. Cependant, chaque mission a des contraintes et un cahier des charges différents concernant la résistance aux radiations, la puissance consommée et la température. Pour les missions SO et PSP, l’instrumentation scientifique est placée derrière un bouclier thermique destiné à protéger la charge utile scientifique des températures très élevées. Néanmoins les instruments sont tout de même soumis à un gradient de température variant entre -150° C et 100° C.

Search-coil avec préampli intégré dans le pied

L’électronique du magnétomètre search coil actuellement fournie par le LPC2E fonctionne dans une gamme de température variant entre -50°C et 80°C. En pratique cette limitation contraint les search coil embarqués pour ces missions à disposer d’une ligne de chauffage afin de pouvoir fonctionner aux basses températures . Cette ligne de chauffage à elle seule consomme 2W tandis que l’instrument consomme 270 mW pour une alimentation ±12V !!!

C’est pour pallier à ce problème qu’une R&D préamplificateur basse température a débuté en septembre 2018 (pour plus de détails voir la section consacrée aux perspectives de recherche).

2 – R&D préamplificateur pour antenne électrique

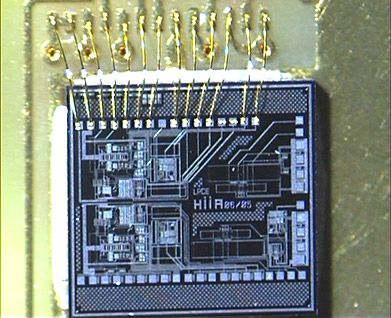

Il s’agissait de développer un préamplificateur très haute impédance d’entrée, faible bruit en technologie ASIC. L’objectif était d’améliorer la mesure du champ électrique en utilisant des antennes électriques comme capteur. Cette étude R&D financée par le CNES a permis de concevoir un circuit ASIC BiCMOS en technologie AMS 0.8 µm. La fonderie a été réaliser via le CMP Grenoble. Le circuit ainsi obtenu a été testé avec succès, en partie sous pointe à la station de radioastronomie de Nançay. Ce travail a donné lieu à une publication.

Préamplificateur ASIC à haute impédance d’entrée pour la mission TARANIS. Y. Kebbati (LPC2E, 2005)

III – Partie Convertisseur analogique numérique de la chaine instrumentale

1 – R&D Amélioration de la résolution des convertisseurs analogique/numérique

Par la méthode Boostrap

Dans le cadre d’une étude de faisabilité, nous avons développé une nouvelle technique d’amélioration de la résolution des convertisseurs analogique numérique. Cette technique se base sur le principe statistique « bootstrap ». L’algorithme a été validé sous Matlab et l’architecture matérielle décrite en VHDL. Une synthèse FPGA sous environnement MaxplusII a été faite afin d’évaluer les performances hardware de notre algorithme. Cette étude a donné lieu à deux publications.

2- R&D Amélioration de la résolution des convertisseurs analogique/numérique

Par la méthode d’interpolation

Dans ce travail, nous avons développé une méthode permettant l’utilisation d’un convertisseur analogique numérique CAN basse résolution dans une chaine instrumentale haute résolution. En effet, l’utilisation d’un CAN haute résolution augmente d’une part le coût de la chaine instrumentale et d’autre part limite la bande passante des signaux qui peuvent être traité. Partant de ce constat, nous avons développé une méthode basée sur l’interpolation du signal issu du convertisseur. Cette étude a permis d’améliorer la résolution d’un CAN 12 bits en le faisant fonctionner comme un 16 bits. L’algorithme d’interpolation a été implanté sur cible FPGA cyclone V d’Altera. Ce travail a donné lieu à l’encadrement de deux stages de master et à deux publications.

IV – Partie traitement numérique, par intégration ASIC/FPGA, de la chaine instrumentale

1 -Développement d’une méthodologie de conception matériel à base de modules génériques VHDL/VHDL-AMS en vue d’une intégration de systèmes de commande électriques

Malgré leur flexibilité et leur intérêt économique, les solutions numériques d’implantation de type logiciel ne s’imposent plus aujourd’hui comme les seuls choix de conception de commande de systèmes électriques. En effet, des solutions plus spécifiques du type matériel (FPGA, ASIC) semblent mieux répondre aux contraintes technologiques actuelles ou à venir. Toutefois, malgré l’avènement d’outils et de langages CAO performants, ces solutions restent encore trop coûteuses et complexes à mettre en œuvre. L’objectif des travaux effectués est d’offrir aux concepteurs de systèmes électriques une approche de description architecturale adaptée aux contraintes d’implantation sur un matériel cible. C’est ainsi qu’une méthode basée sur les principes de la conception modulaire d’Adéquation Algorithme Architecture et sur l’élaboration d’une bibliothèque de modules spécifiques a pu être développée pour différents cas de commande. Ainsi, l’architecture de la commande directe du couple d’un moteur asynchrone a pu être établie en suivant cette méthode et son efficacité a pu être validée en comparant ses performances d’implantation à celles d’approches plus classiques de conception. Par la suite, le cas d’une commande de vitesse « sans capteurs » d’un moteur à réluctance variable et celui d’un dispositif d’électronique de puissance ont également pu montrer l’efficacité de la méthode proposée. A partir de ce dernier cas de conception, une méthodologie globale du mode de conception modulaire a finalement pu être élaborée en développant une bibliothèque de modèles comportementaux de la commande et du système électrique associé. Ces modèles ont été décrits en langages VHDL et VHDL-AMS de manière à respecter la mixité (numérique et analogique) des éléments qui composent le système électrique. Cette approche permet aussi de prévoir le cas d’une intégration mixte du système, ouvrant par la même de larges perspectives de conception dans ce domaine d’application. Ce travail a fait l’objet de plusieurs publications et communications.

2- R&D Logique RSFQ (supraconducteurs) pour applications spatiales

Depuis la découverte de la supraconductivité et de la jonction Josephson (JJ) dans les années 1960, une nouvelle aire de la microélectronique est apparue. En effet, les circuits intégrés supraconducteurs actuels utilisent les caractéristiques inhérentes à la JJ pour atteindre des performances (rapidité de traitement des données à haute fréquence, une faible dissipation de puissance…) jusqu’alors inégalé par les circuits CMOS. Ces caractéristiques peuvent être résumées :

– Disponibilité de lignes de transmission supraconductrice microstrip capables de transférer des ondes picosecondes avec une vitesse approchant celle de la lumière.

– Les JJ peuvent être utilisées comme interrupteur/mémoire ultrarapide ( picoseconde).

– Les JJ peuvent être facilement adaptés en impédance avec les lignes microstrip ce qui permet un transfert balistique des ondes générés. Ainsi, les JJ ont une dissipation de puissance très faible de par les faibles tensions utilisées.

L’élément élémentaire RSFQ consiste en un interféromètre composé d’une diode Josephson couplée avec un élément inductif supraconducteur et des lignes de transmission à base de diodes Josephson. Cette architecture permet de transférer ou de mémoriser une impulsion logique (quanta de flux magnétique) sans atténuation ou distorsion à des fréquences de plusieurs centaines de gigahertz (750 GHz) et avec une puissance consommée extrêmement faible (< 100 nW/porte). Par ailleurs à la différence de la JJ, les circuits RSFQ nécessitent uniquement une alimentation continue DC. De plus, en comparaison avec la technologie CMOS actuelle, ils utilisent une technologie de fabrication relativement simple ne nécessitant pas de dessin submicronique profond.

L’état de l’art de la logique RSFQ montre que cette technologie est viable pour différents domaines d’application. En effet, nous assistons ces dernières années, à une augmentation importante du nombre de circuits développés et des performances atteintes (vitesse, puissance consommée, densité d’intégration) et à l’apparition de nouvelles technologies : nouvelles JJ, technologie submicronique… Dans le domaine spatial, la génération du froid reste un verrou problématique et cette technologie n’y a pas encore trouvé sa place malgré les besoins croissants en matière de puissance de calcul. Cette R&D a abouti à un contrat avec la société ALCATEL Space pour laquelle nous avons fourni un rapport de prospection sur l’utilisation de la logique RSFQ pour les futures missions spatiales. Ce travail a donné lieu à une publication.

Perspectives de recherche

I – Perspective à moyen terme (≤ 5 ans)

Développement d’un instrument search-coil BF à sortie numérique et pouvant fonctionner dans une gamme de température de -150° C à 100° C.

L’objectif de l’étude est de développer un instrument magnétomètre search-coil BF 10 Hz – 20 kHz à sortie numérique du type plug&play et pouvant fonctionner dans une gamme de température large entre -150° C et 100° C. Pour ce faire, un développement d’une électronique adaptée sera nécessaire. Pour atteindre notre objectif, nous utiliserons la technologie microélectronique pour intégrer la chaîne instrumentale électronique du search-coil : préamplificateur, filtre et convertisseur analogique-numérique. Les développements se feront en trois principales étapes :

– Intégration ASIC du préamplificateur du search-coil pour un fonctionnement entre -150°C et 100°C (cf : R&D préamplificateur basse température pour search-coil)

– Développement d’un CAN ASIC 16bits et du filtre

– Intégration de l’ensemble de la chaîne électronique.

Collaborations

Cette étude se fera via l’encadrement d’une thèse en collaboration avec le laboratoire IRFU du CEA Saclay qui a déjà une expérience dans les développements ASIC basse température. Les fonderies des circuits ASIC se feront à travers les réseaux CMP ou Europractice afin de réduire les coûts de développement en bénéficiant des prix dédiés aux universités et à la recherche.

Technologie et verrous

Le choix de la technologie et l’encapsulation constituent les principaux verrous de cette R&D.

La technologie impactera directement les performances des circuits et permettra ou non d’atteindre notre objectif de fonctionnement en basse température -150° C. En effet, les technologies actuelles sont destinées pour un fonctionnement entre -50° C à 80° C. Ainsi, une phase d’étude technologique approfondie sera nécessaire. Cette étude se matérialisera sous la forme d’une première fonderie dédiée à des circuits de base. Le but est qu’après les tests de retour de fonderie, une modélisation plus fine du fonctionnement des transistors en basse température sera alors possible. Cela permettra ainsi de compléter les modèles fournies par le fondeur. Nous prévoyons que les développements se feront probablement en technologie AMS 0,35 µm car cette technologie est maintenant à la fois très répandue, robuste (car disponible depuis plusieurs année) et à faible coût. Toutefois, nous resterons attentifs aux dernières avancées en microélectronique avant de choisir la technologie appropriée permettant d’atteindre notre objectif.

L’encapsulation est un problème récurrent dans le spatial et les basses températures que nous souhaitons atteindre ne font qu’augmenter les contraintes. Il faudra donc prendre en compte ce problème dès les débuts du design des circuits pour, d’une part, ne pas altérer les performances après la fonderie et, d’autre part, pour les reports de puce sur le PCB. En effet, dans le cas de l’instrument magnétomètre search-coil du LPC2E, l’électronique de pré-amplification se trouve généralement dans le pied du capteur search-coil.

Contact LPC2E : Youssef.Kebbati@cnrs-orleans.fr